Introduction to DIY Glitter Tumblers

DIY glitter tumblers are a fun and creative way to personalize your drinking experience. They sparkle, shine, and reflect your unique style. Whether you’re making one for yourself or as a gift, these tumblers can add a touch of glam to everyday life.

Creating a glitter tumbler involves a series of steps that ensure the end product is both beautiful and durable. From selecting the right supplies to applying and sealing the glitter, each phase is crucial. This guide will walk you through the process, offering tips and tricks along the way.

Glitter tumblers are not only a trendy craft but also a project that can give you a sense of accomplishment. With a little patience and creativity, you can make a tumbler that stands out. Perfect for coffee lovers, craft enthusiasts, or anyone looking to add some sparkle to their drinkware collection, making a glitter tumbler is an enjoyable project for all skill levels.

In the following sections, we’ll cover the essential supplies you need, the steps to decorate your tumbler, how to seal the glitter, and more. So grab your supplies, and let’s get started on creating your very own glitter tumbler!

Essential Supplies for Making a Glitter Tumbler

Gathering the right supplies is the first step to creating a dazzling glitter tumbler. To start off, you need a good-quality, smooth-surfaced tumbler. Stainless steel is a top choice for durability. Next, choose fine glitter in your desired colors. The finer the particles, the smoother the finish on your tumbler. You’ll also need a sealant like epoxy resin to lock in the glitter and give that glossy sheen. Silicone brushes or foam brushes are great for applying both glue and the sealant evenly without leaving brush marks. Additionally, grab a clear glue or a mod podge to adhere the glitter to the tumbler. To minimize messes, have painter’s tape on hand to cover parts you don’t want glittered. Lastly, don’t forget a rotating stand or a hand turner. It helps apply the glitter and sealant uniformly around the tumbler’s surface.

Ensure you work in a dust-free area to avoid particles sticking to the wet surfaces. With these supplies ready, you’re set to start the glitter tumbler project!

Preparing Your Tumbler for Decoration

Before you dive into the fun part of decorating your glitter tumbler, it’s key to get your tumbler ready. Proper preparation will help the glitter and adhesive bond well, creating a flawless, long-lasting finish. Here’s how to prepare your tumbler for decoration:

- Clean the Tumbler: Make sure the tumbler is free of dust, grease, and fingerprints. Use rubbing alcohol and a lint-free cloth to wipe it down thoroughly.

- Tape Off Areas: Use painter’s tape to cover any parts you don’t want to decorate, like the rim or the bottom. Press down firmly to ensure no glitter sneaks underneath.

- Roughen the Surface: Lightly sand the tumbler if it’s too smooth. This step gives the glue something to grip on to. Be gentle and aim for a light scuff, not deep scratches.

- Wipe Down Again: Go over the tumbler one more time with rubbing alcohol to remove any dust from sanding.

- Set Up Your Workspace: Lay down paper or a drop cloth to catch excess glitter. Having a dedicated workspace keeps things clean and organized.

Once you’ve followed these preparatory steps, your glitter tumbler is primed and ready for the next stage. You’ll find the glitter and adhesive applies more evenly and the end result much more satisfying when starting with a well-prepped surface.

Step-by-Step Process: Applying the Glitter

Now that your tumbler is ready, it’s time to move on to the exciting part: applying the glitter. Follow these steps to ensure a smooth, even coat of sparkle on your tumbler.

- Apply the Adhesive: Start by applying a thin, even layer of glue or mod podge over the entire surface of the tumbler. Use silicone or foam brushes for a smooth application.

- Sprinkle the Glitter: While the adhesive is still wet, sprinkle the fine glitter over it. Make sure to cover all areas. Rotate the tumbler as you sprinkle to get an even coat.

- Tap Off Excess: After you’ve applied the glitter, gently tap the tumbler to shake off any loose particles. This will help to ensure a neat finish.

- Let it Dry: Allow the adhesive to dry completely. This usually takes about an hour or as per the glue manufacturer’s instructions.

- Apply a Second Coat: If you want more coverage, apply a second layer of glue and repeat the glittering process. Then, let it dry as before.

- Remove the Tape: Once the second layer is dry, carefully peel off the painter’s tape.

Sealing the Glitter: Ensuring Longevity

After applying and letting the glitter settle, it’s vital to seal it properly. This ensures the glitter tumbler lasts a long time and remains shiny. Here’s how you seal the glitter:

- Mix the Epoxy Resin: Follow the instructions on your epoxy resin. Mix it carefully according to the package directions for best results.

- Apply the Epoxy: Using a silicone brush, apply a thin, even layer of epoxy resin over the glittered surface. Turn the tumbler slowly as you apply, making sure to cover all glittered areas.

- Pop Air Bubbles: After applying the epoxy, carefully check for air bubbles. If you see any, use a heat gun or hairdryer to gently pop them. Keep the tool moving to avoid overheating any spot.

- Let it Cure: Place the tumbler on a rotating stand. Allow it to turn slowly as the epoxy cures. This can take several hours to a full day. Follow the epoxy’s drying time instructions.

- Check for Smoothness: Once cured, feel the tumbler. If it’s not smooth, you can sand it lightly. Then, apply one more epoxy coat if needed.

By sealing your glitter tumbler properly, you protect the sparkly surface from wear and tear. The epoxy resin not only seals in the glitter but also adds a glossy finish that enhances the tumbler’s overall look. Be patient through this process to ensure the epoxy sets well and you’re rewarded with a durable, eye-catching tumbler.

Customizing Your Glitter Tumbler with Additional Decorations

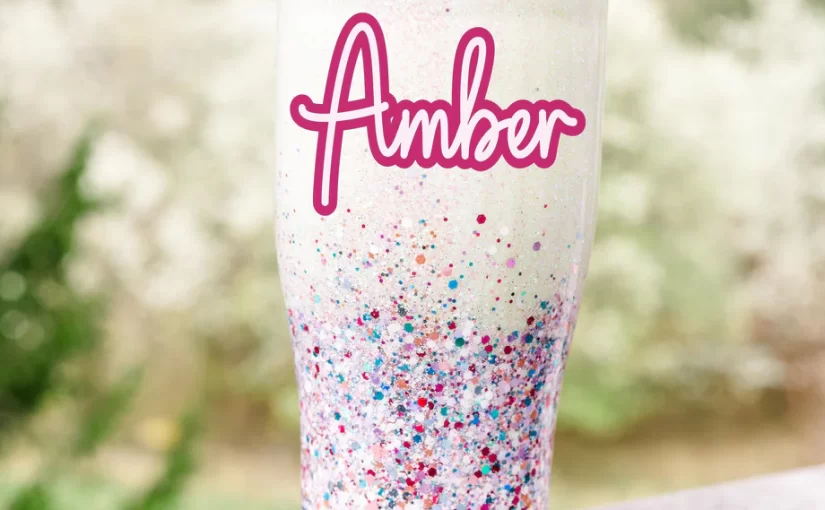

Once you’ve sealed your tumbler with epoxy, it’s ready for extra customization. There are countless ways to make your glitter tumbler even more special. Here are some ideas to inspire your creativity:

- Add decals or vinyl stickers: Choose images or phrases that reflect your style. Apply them carefully on top of the cured epoxy layer.

- Attach charms or gems: Using a strong adhesive, place sparkling gems or unique charms around the tumbler for extra flair.

- Use a second glitter color: Create a gradient effect or patterns with another glitter shade. Seal it again with epoxy for durability.

- Personalize with a name or quote: Use a permanent marker or have a custom vinyl text made to add a personal touch.

- Implement fabric or washi tape: For a textured feel, add strips of fabric or washi tape in designs or borders.

Before adding these elements, always ensure the epoxy layer is fully cured and hard. This base gives a solid surface for additional decorations to adhere to. Be careful when using adhesives or sharp tools, and always protect the underlying glitter layer.

By customizing your glitter tumbler with these additional touches, you’ll have a truly unique item. It’s perfect for personal use or as a thoughtful custom gift. Let your imagination run wild and enjoy the endless possibilities of tumbler personalization!

Troubleshooting Common Issues

When creating your glitter tumbler, you might encounter some challenges. Here are some common issues and how to fix them:

Glitter Clumps or Unevenness

- Make sure the adhesive is applied evenly before adding glitter.

- Tap the tumbler gently to spread the glitter more uniformly.

- If clumps form, use a clean, dry brush to smooth them out before the glue dries.

Adhesive Not Sticking

- Ensure the tumbler is clean and free from oils before starting. Use rubbing alcohol for a thorough clean.

- Roughen up the tumbler surface with light sanding to help the glue grip better.

Epoxy Resin Issues

- Mix the epoxy resin thoroughly to avoid poor curing.

- Apply epoxy in a warm, dust-free environment to prevent bubbles and dust settling.

- If bubbles appear, pop them with a heat gun or hair dryer from a safe distance.

Tumbler Not Rotating Evenly

- Check your rotating stand to ensure it’s stable and level.

- Adjust the tumbler on the stand so that it’s centered and balanced.

Decals Peeling Off

- Allow the epoxy to cure fully before applying any decals.

- Press decals firmly and ensure they’re lie flat against the tumbler surface.

Encountering issues while crafting your glitter tumbler is part of the learning process. With these troubleshooting tips, you can overcome common problems to achieve that perfect, sparkly finish.

Tips for Caring for Your Glitter Tumbler

Caring for your glitter tumbler will keep it looking great and lasting long. Here are some tips:

- Hand Wash Only: Avoid dishwashers as heat can damage the epoxy and glitter. Wash by hand.

- Use Mild Soap: When washing, use mild soap. It is gentle and won’t harm the tumbler’s surface.

- Avoid Scrubbing: Scrubbing can scratch the epoxy. Instead, use a soft sponge for cleaning.

- Do Not Soak: Letting your tumbler soak can weaken the epoxy seal. Just wash and rinse.

- Dry Immediately: After washing, dry your tumbler right away to avoid water spots or streaks.

- Avoid Extreme Temperatures: Don’t leave your tumbler in hot cars or freezers. Extreme temps can cause damage.

- Store Safely: Keep your tumbler in a place where it won’t get bumped or dropped.

With good care, your glitter tumbler will stay shiny and durable. Enjoy using it every day!